What is a BIM Execution Plan (BEP) and Why Should I Care?

We’ve probably all heard the phrase, “It’s all fun and games until someone gets hurt.” I often think of this phrase in conversations about the

CAD BLOX is a full service agency providing construction technology, modeling, and coordination services for masonry contractors.

We’ve probably all heard the phrase, “It’s all fun and games until someone gets hurt.” I often think of this phrase in conversations about the

The construction sector as a whole has lagged other sectors in embracing environmentally conscious improvements. That’s no surprise, as the old ways have more or

As it did with so many trends, the pandemic has accelerated venture capital investment in the construction sector. Has the pandemic created “the perfect storm”

Software tools provide a variety of benefits along with their demands. Virtual design and construction (VDC) is no exception. While large firms have embraced VDC

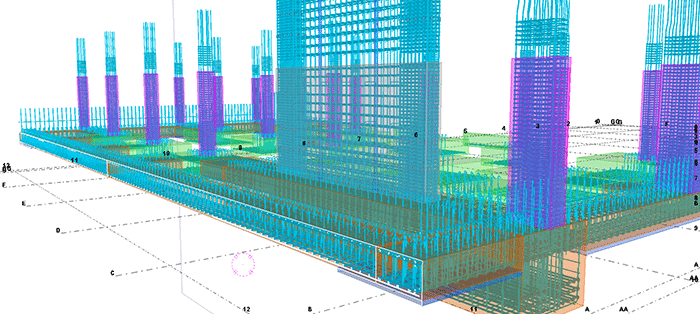

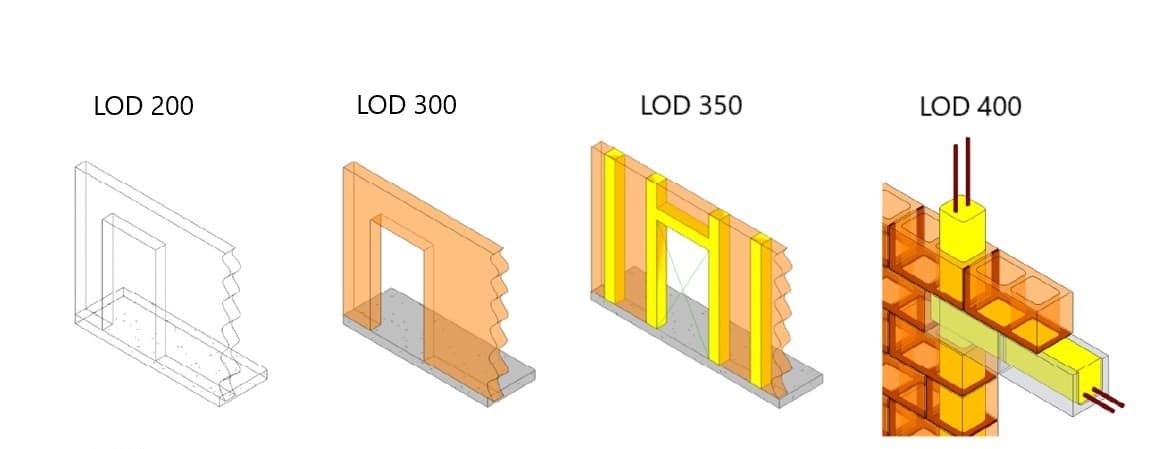

Level of Development (LOD) is a set of BIM (building information modeling) communication standards designed to help AEC professionals communicate accurately and precisely as projects

Artificial intelligence, robotic masons, virtual reality, augmented reality, mixed reality. There’s a lot of new technology to keep track of these days, and learning how

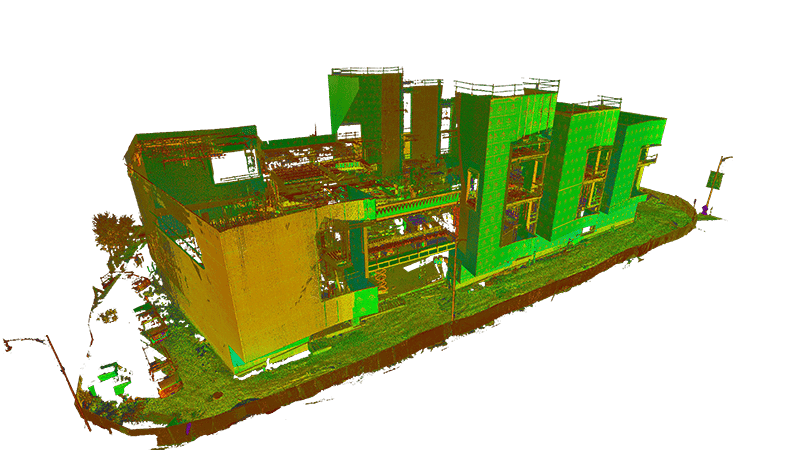

You may have been hearing about LiDAR, light detection and ranging, in the last couple of years or so, as it’s becoming more used in

Has the age of robotics in construction finally arrived? Yes, most definitely. And robots offer a chance to advance an industry that needs it. Much

COVID has been a body blow to most of us, but there are some bright spots we can notice. In scrambling to adapt to greater

Prefab construction technology is gaining ground in the U.S., and for good reason. It offers a variety of benefits across all sectors where it’s used